Flow Direction and Impeller Blade Angle:

The impeller in an Axial Flow Pump is specifically designed to move the fluid along the axis of the pump , which results in a linear flow as opposed to the radial flow seen in centrifugal pumps. The blade angle of the impeller plays a crucial role in determining the velocity at which the fluid is propelled and the direction in which the flow is generated. A high blade angle results in a greater velocity of the fluid, which is advantageous in applications requiring high flow rates, but at the expense of pressure (head). On the other hand, a low blade angle typically produces a higher head but at a lower flow rate. This trade-off is critical in designing pumps for applications where either high flow or high pressure is prioritized. Adjusting the blade angle can optimize the pump's performance for the specific system demand , balancing flow rate with the necessary operating pressure. In low-head applications , such as irrigation systems or flood control, a higher blade angle is preferred to move large volumes of fluid efficiently. In high-pressure applications, such as power plant cooling, a lower blade angle is more suitable.

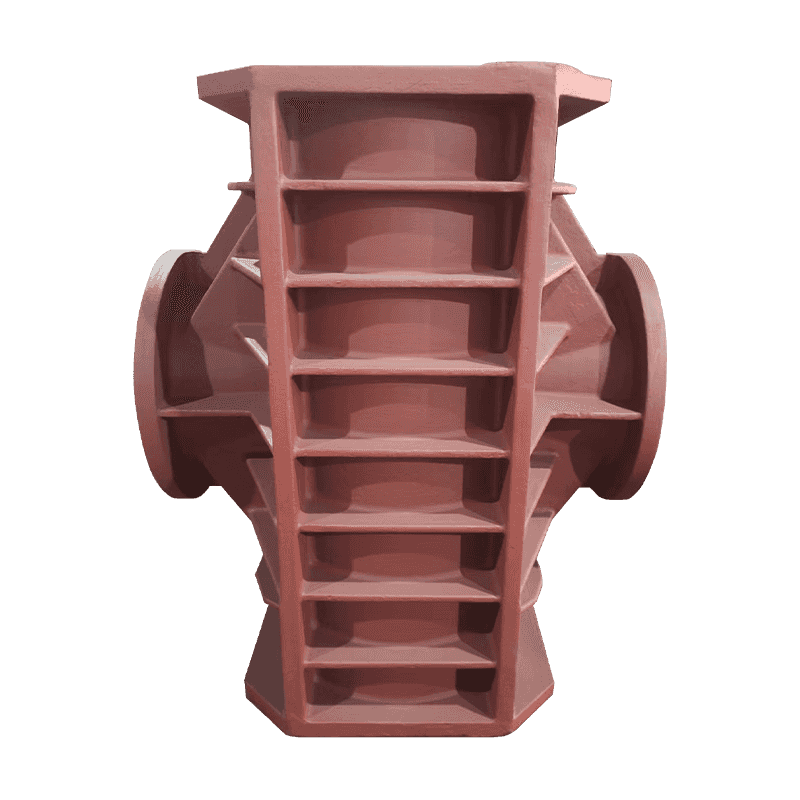

Blade Number and Shape:

The number and shape of the impeller blades influence both the fluid dynamics within the pump and the overall efficiency . More blades typically improve the smoothness of the flow, reducing turbulence and ensuring that the fluid moves with greater stability. This is especially important in reducing fluid separation and improving energy transfer . However, more blades can introduce higher drag , increasing energy consumption, and possibly leading to lower efficiency at higher speeds. Conversely, impellers with fewer blades tend to reduce drag and can be more efficient at higher flow rates, but this can lead to more turbulent flow , which can cause increased wear and tear on the pump components. The shape of the blades, whether straight , curved , or variable-pitch , also influences the flow behavior. Curved blades tend to produce a smoother flow and are less prone to causing flow separation , which minimizes turbulence and increases the pump's overall efficiency . Variable-pitch blades can be adjusted to optimize flow characteristics for changing operational conditions, making them more adaptable for variable flow rates and pressure requirements.

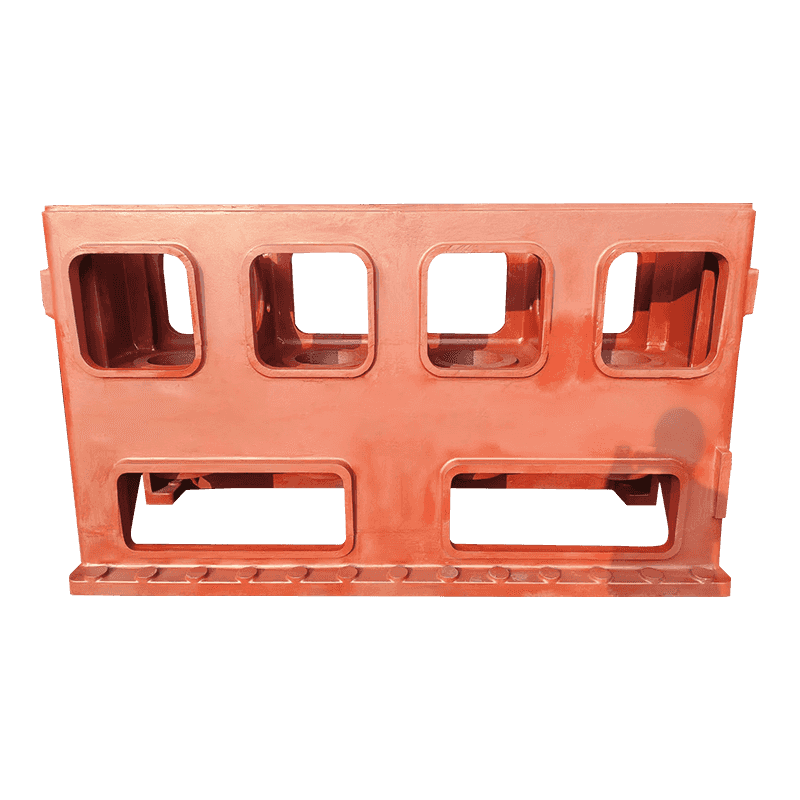

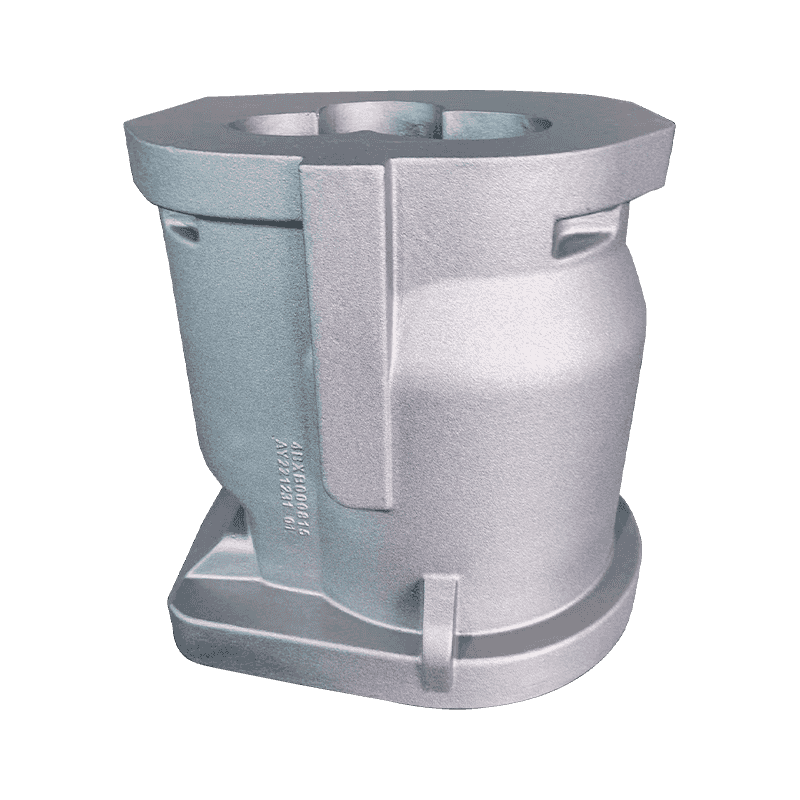

Impeller Diameter and Size:

The diameter and overall size of the impeller are crucial factors in determining the pump’s capacity and flow characteristics . A larger impeller diameter enables the pump to move a greater volume of fluid per rotation, thus increasing the flow rate . However, this increased flow capacity also requires more power to operate the pump, as the larger impeller faces greater resistance in the fluid. Therefore, larger impellers are more suitable for applications where high-volume, low-pressure fluid movement is necessary. Conversely, a smaller impeller diameter is better for handling lower flow rates but with higher pressure output, making it ideal for high-head applications. The size of the impeller must be carefully matched to the system's operational needs to balance flow and head requirements while minimizing energy consumption. In high-demand applications, such as flood control systems or large irrigation networks , larger impellers may be chosen for their ability to handle large flow volumes, while smaller impellers may be used in pressurized systems where specific pressure levels are critical.

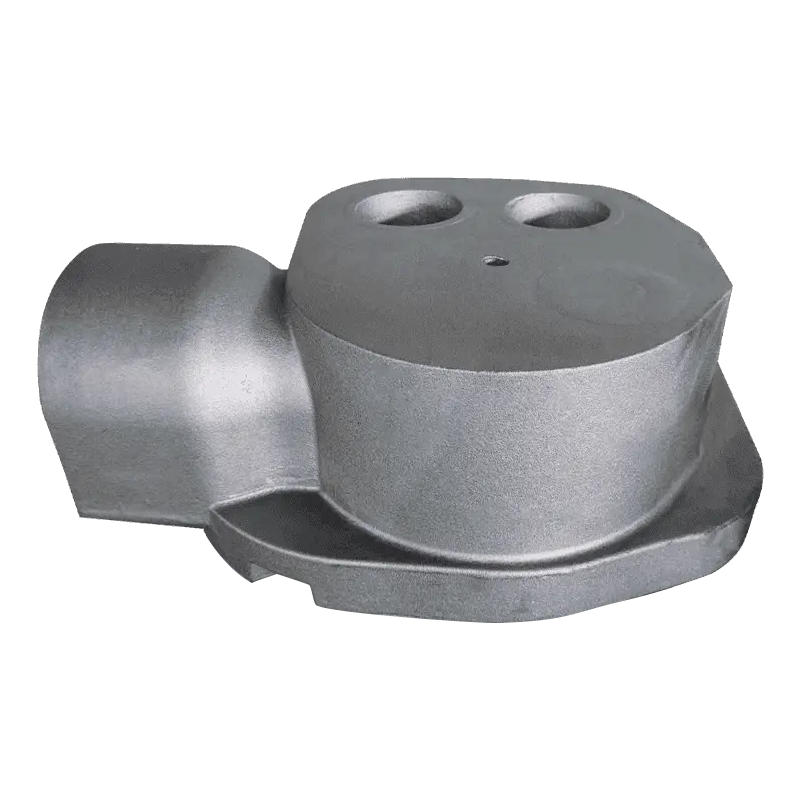

Impeller Blade Curvature and Sweep:

The curvature and sweep of the impeller blades influence how the fluid is accelerated and directed through the pump. Curved blades are generally more effective at reducing flow turbulence and preventing fluid recirculation , which can lead to energy losses and efficiency reductions. The design of the blade sweep —whether forward or backward-curved —also plays a significant role in directing the flow of the fluid more effectively. Forward-swept blades tend to push fluid in a more linear manner , which can be advantageous for low-pressure, high-flow applications like irrigation systems. Backward-swept blades , on the other hand, can reduce the likelihood of cavitation by stabilizing the flow and improving the pump's ability to handle higher-pressure conditions without causing fluid instability. The sweep angle can influence the flow velocity at different points in the pump, affecting overall energy efficiency and performance.

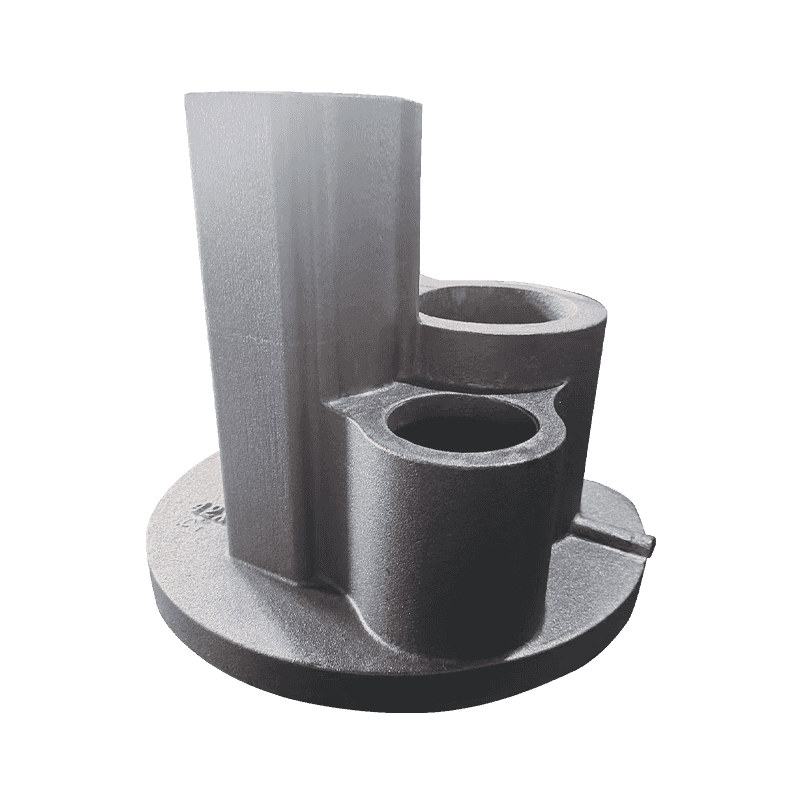

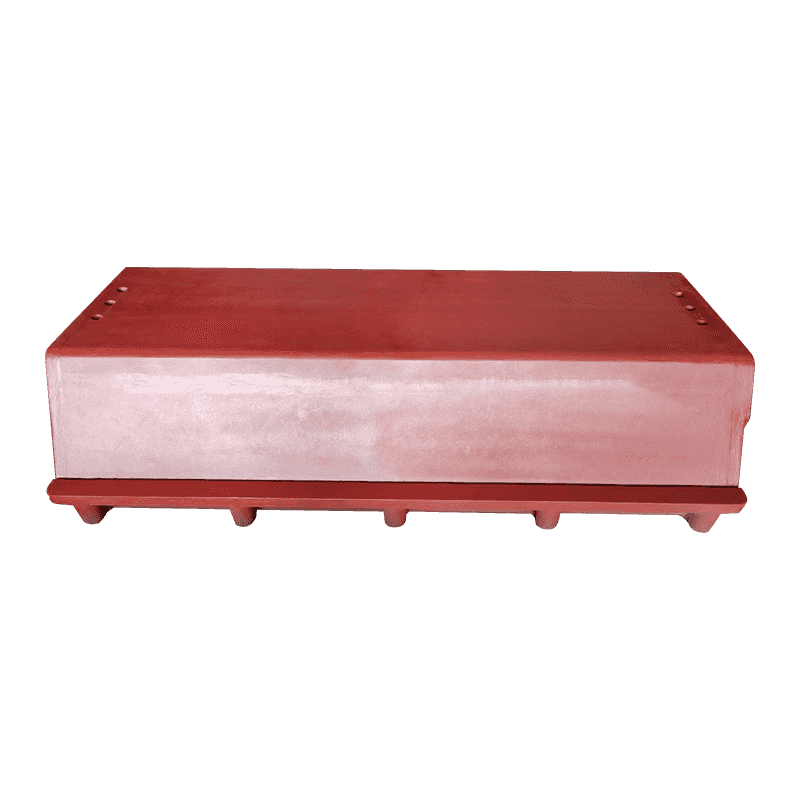

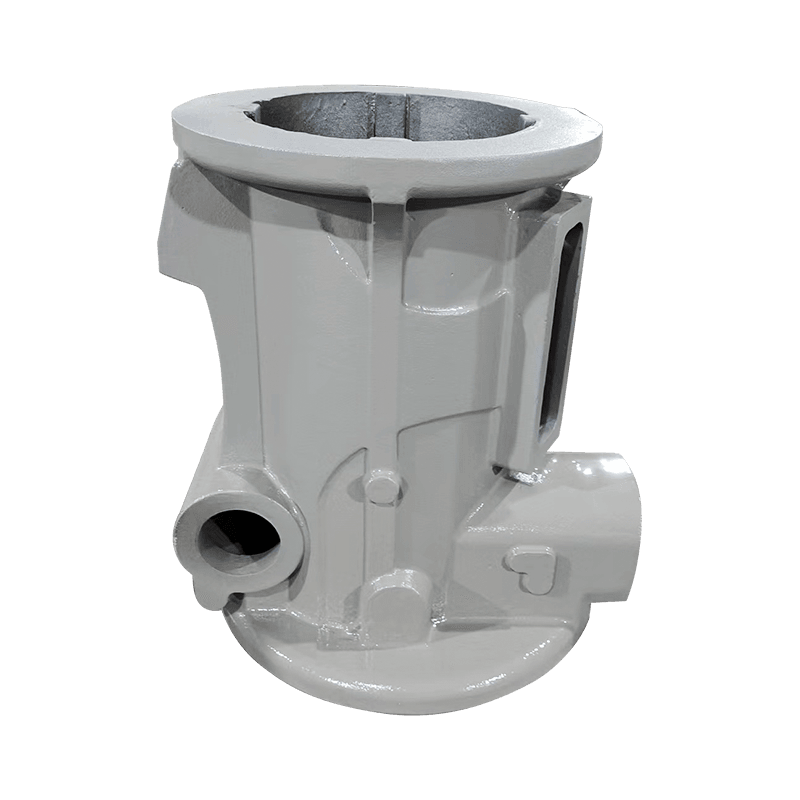

Impeller Material and Durability:

The material of the impeller is a significant factor in the pump’s durability , particularly when handling abrasive or corrosive fluids . Materials such as stainless steel and bronze are commonly used for their corrosion resistance and strength . In applications involving abrasive particles (such as in mining or wastewater treatment), materials like high-chromium alloys or ceramics may be chosen for their ability to withstand wear and erosion. Composite materials or plastic impellers are sometimes used in systems that do not require extreme durability but prioritize cost-effectiveness and lightweight designs. The choice of material impacts the overall longevity of the pump, with high-quality, corrosion-resistant materials ensuring that the pump remains reliable and efficient even in harsh environments. Furthermore, the material must be selected to withstand the temperature , pH , and viscosity of the fluids being pumped.